Custom Made Lithium Ion Battery Packs

We design and manufacture custom lithium ion battery packs, let our batteries power your business success.

Technical Support

Engineering Team

What are custom Lithium ion battery packs?

Lithium-ion batteries are a type of rechargeable battery which are commonly used in various electronic devices such as laptops, smartphones, power tools, and electric vehicles.

Custom Lithium ion battery packs are designed and manufactured to meet the unique needs of a particular device or application. The goal is to create a battery pack that seamlessly integrates with the device it powers.

Some common characteristics and features of custom Lithium ion battery packs include:

- 3D drawing of outer case

Voltage

Capacity

Size and Shape

Chemistry: Lithium ion, Li-polymer, LiFePO4

Connectors and Terminals

Protection Circuitry

- BMS

Certifications

How can we help you build the custom Lithium ion battery packs?

Our design implementation strategies include:

- Assess the customizability of the project as a whole first

- Project specific to each responsible engineer

- Good at problem solving, and course correcting

- Test demos and make notes to better customize the production process for mass production.

What Kind Lithium ion battery can we offer?

- Standard Lithium ion Cylindrical Battery Pack

- widely used for GPS, barcode scanner,laptops, flashlights,smart locks etc.

- High C rate Lithium ion Cylindrical Battery Pack

- widely used for vacuum cleaner, auto-mower, power tools, etc.

- Standard Li-polymer Battery Pack

- widely used for smart phone, GPS, smart watch, TWS earbuds,conntrollers,wireless mouse and keyboard, E-bike, bluetooth headsets and speakers etc.

- Hi-Discharge rate Lithium ion Cylindrical Battery Pack

- widely used for drone,delivery UAV, Agricultural drones etc.

- LiFe Po4 Battery Pack

- widely used for UPS, energy storage, AGV,5G base stations, two-wheelers, heavy-duty trucks, electric ships and other fields

Gerneral Purchasing Process Guide:

- Inquiry: we need basic information about battery after communication back and forth, like cell size, voltage, working current, max working current, 3D case drawing, BMS information and others.It will be better if you send us battery sepecification.

- Quotation/Payment term/Derlivery term

- Samples Arrangement after quotation approval

- Samples Approval

- Placing order

- Arrange down payment

- Mass production

- Quality Testing by customers

- Arrange rest payment

- Delivery and clear custom in China

- Ship on Board

Get In Touch...

UPS backup energy

Home Solar Energy

Vacuum cleaner

Bluetooth Speaker

EV Fork

Personal Notebook

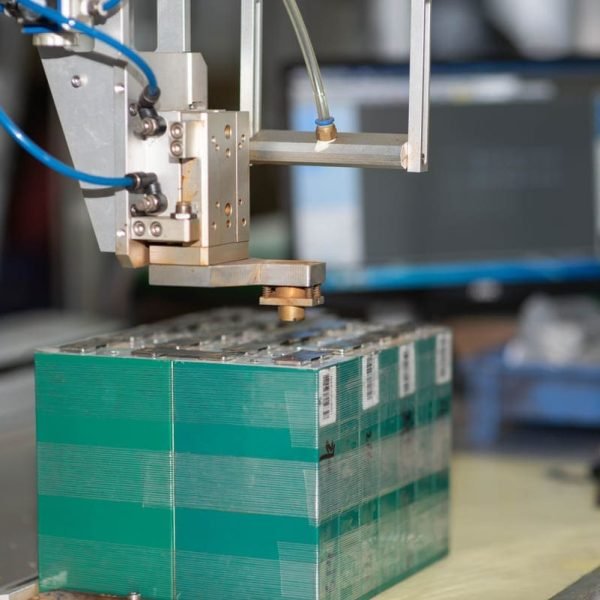

The Battery Manufacturing Process

1. After the samples and battery specification are confirmed, we will start mass production soon after receiving the customer order and deposit.

2. Evaluate supplier, and test the quality of cell and PCM samples, till samples are approved.

3. Buy all the materials from the qualified supplier which are CE, ROHS,UKCA certified.

4. Spot-check cells capacity and fully check the voltage and internal resistance of cells before mass production.

5. Start mass production.

6. Fully check the battery quality during mass production, called IPQC.

7. After batteries are finished, fully check their performance, such as appearance, voltage, working current, over-working current, internal resistance etc. For the multiple battery pack, we add the life cycle testing before shipment.

8. Package and shipment.

Quality Inspection

Process during production

IQC

When we receive incoming materials from our suppliers, we conduct spot-checks on samples to assess their quality. If the samples pass the quality inspection and meet our standards, we proceed to transfer them to our incoming materials warehouse. From there, our production team will retrieve the approved materials for trial orders and, subsequently, for mass production based on the specified order quantity.

However, if the spot-check reveals that the samples do not meet our quality requirements and are not approved, we will arrange to return these materials to our supplier. This ensures that we maintain high standards and only use materials that meet our quality criteria in our production processes.

IPQC

Before proceeding with trial orders or mass production, we follow a thorough process to ensure the quality of the cells used in our products. This involves spot-checking the capacity of the cells and conducting a comprehensive assessment of their performance, including outward appearance, voltage, and internal resistance. Only cells that meet our quality standards are allowed to move forward to the production line.

Any cells that are found to be non-compliant during the spot-check are identified as “NG batteries” (No Good) and are immediately removed from the production process. These rejected batteries are then returned to the supplier for further analysis and resolution.

Once the approved cells have been soldered with PCM (Protection Circuit Module), we subject the batteries to a rigorous performance check. This assessment includes evaluating voltage, internal resistance, and overcurrent capabilities, among other factors. This meticulous testing ensures that the batteries used in our products meet our high-quality standards and guarantees the reliability and safety of the final goods.

OQC

When the batteries are depleted, we will conduct a thorough assessment of their performance based on the specifications or drawings confirmed by the customer. This assessment includes inspecting the outward appearance, battery label, printing, wires or wire connectors, voltage, internal resistance, and over current protection. If all these parameters meet the required standards, we will proceed with packing the batteries into cartons.

However, if any of these aspects do not meet the specifications, the batteries will be returned to the Quality Control (QC) team for further analysis and necessary adjustments.

In the case of multiple battery packs, such as two cells in parallel, five cells in series, or a 2P6S battery pack, we will subject them to life cycle testing before shipping.

This testing involves simulating real-world usage conditions to evaluate the battery pack’s performance and durability over an extended period. Only those battery packs that pass the life cycle testing will be considered suitable for shipment.

Our commitment to quality assurance ensures that only reliable and fully compliant batteries are delivered to our customers.

After-sales service

Batterea.com offers after-sales services that go far beyond regular batteries and custom-made batteries. They are a comprehensive, continued service package for customers and the core of our company philosophy. Our members of staff are available to you anytime for all possible questions regarding our range of services.

A high level of customer satisfaction is our basis for successful long-term partnerships.

When you receive our battery, if there are any problems, no matter what the problem is, we will face them and reply to you with our solution as soon as possible.

The Shipping Process

Step 1

Design,Manufacturing and book for shipment

We buy the materials to meet your order requests, then start the mass production under our quality control. In the meantime, we will send UN38.3 documents to the forwarder for booking cargo space to avoid any delay.

Step 2

Packing the Boxes for Delivery,stick UN3480 on the carton

After production, our team will pack your order into cartons, stick UN3480 label on the carton.

Step 3

Customs Clearance and Loading

Once your order is packed, we load them onto vans and wait for them to be cleared by Customs.

Step 4

International Delivery

Once cleared, your order will then be shipped to you through international waters. You’ll receive a bill of lading in your email once the cargo is on board and a bill of lading by telex released when your shipment arrives.

Request for a quote today

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.